Water supply from a borehole or well

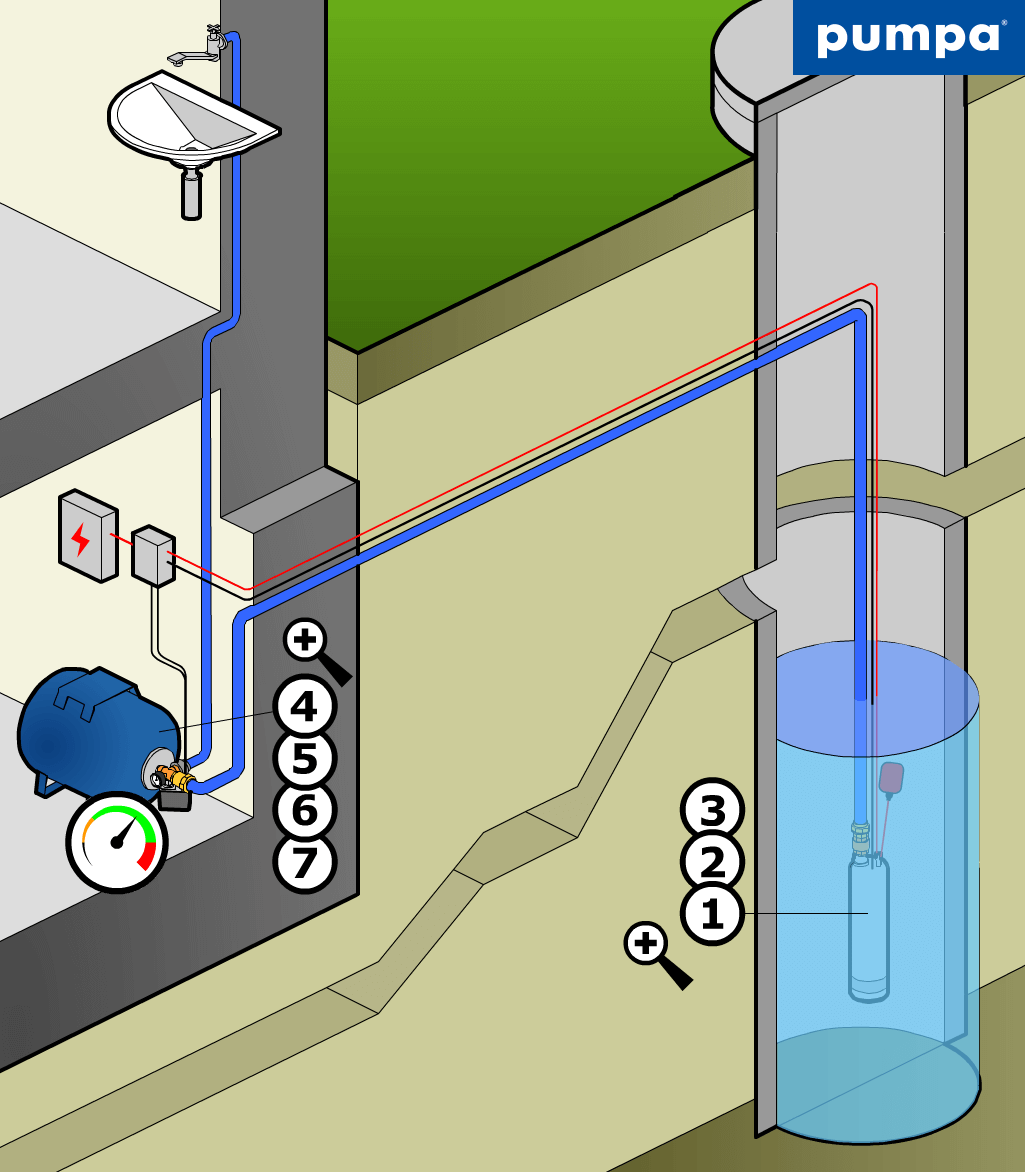

Water supply from the well (submersible pump + pressure tank in the house)

How the pump for wells works

Principle

To pump water from the well from a depth of more than 8 m, we will use a submersible pump designed for the well (1), which in a set with dry running protection (3), a check valve (2), a pressure tank (7) with a pressure gauge (5) and a pressure switch (6) installed on five-way fittings (4), form a pressure booster pump. When the pressure in the system drops (e.g., by opening the tap) below the set on pressure, the pressure switch automatically switches on the pump and shuts it off when the set cut-off pressure is reached. In case of water shortage in the well and in case we have dry running protection installed, the switching device turns off the pump and protects it from damage. The dry running protection switchgear will then not allow the pump to switch on until sufficient water level in the well has been reached. As a protection against dry running, we can use either submersible probes or a float switch. The float switch can be included in some types of pumps.

For trouble-free operation of the system, it is always necessary to maintain the correct setting of the air pressure in the expansion vessel, which should be 0.2 bar lower than the on (bottom) pressure on the pressure switch. This pressure must be set in the dry state of the vessel, i.e., before the actual installation in the system.

Water supply from the well (surface pressure booster pump + pressure tank in the house)

How a pressure booster pump works

Principle

To pump water from the well from a depth of up to 8m, we can use a complete pressure booster pump. In the well itself, there is a suction basket with a swing check valve (1,2) and optionally dry running protection. The pressure booster pump consists of a pump (3), a pressure tank with a pressure gauge and a pressure switch installed on the five-way fitting. When the pressure in the system drops (e.g., by opening the tap) below the set on pressure, the pressure switch automatically switches on the pump and shuts it off when the set cut-off pressure is reached. In case of water shortage and if we have dry running protection installed in the well, the switching device will turn off the pump and protect it from damage. The dry running protection switchgear will then not allow the pump to switch on until sufficient water level in the well has been reached. As a dry running protection, we can use either submersible probes or a float switch.

For trouble-free operation of the system, it is always necessary to maintain the correct setting of the air pressure in the expansion vessel, which should be 0.2 bar lower than the on (bottom) pressure on the pressure switch. This pressure must be set in the dry state of the vessel, i.e., before the actual installation in the system.

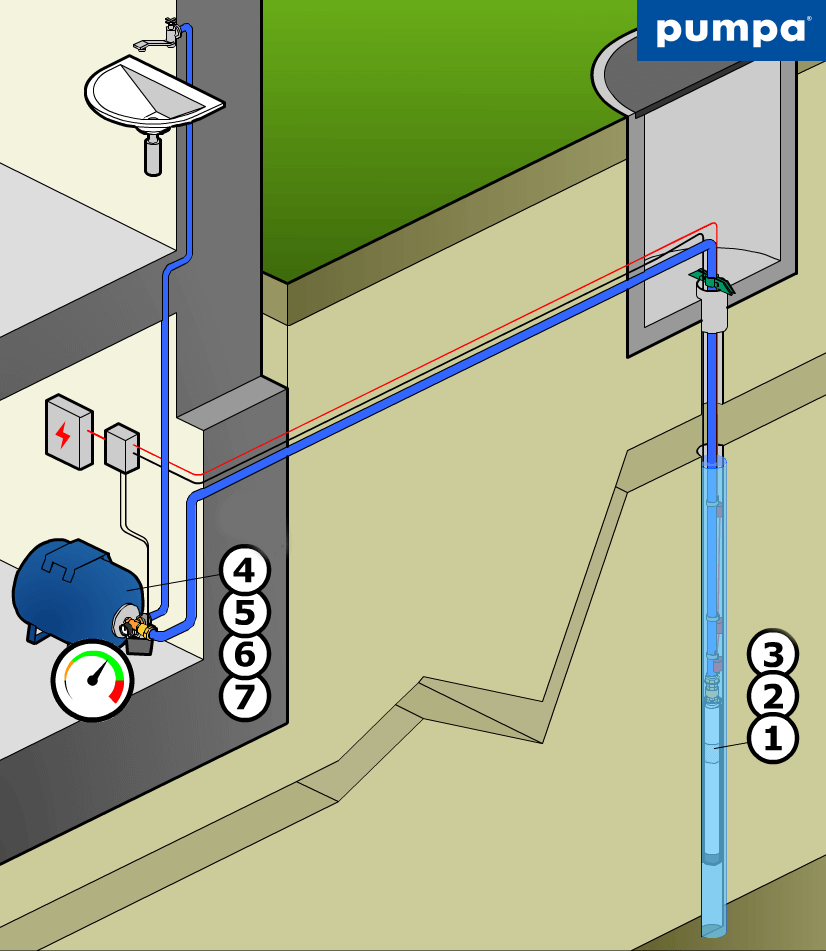

Water supply from the borehole (submersible pump + pressure tank in the house)

How the borehole pump works

Principle

To pump water from the borehole, we will use a submersible borehole pumps (1), which in a set with dry running protection (3), check valve (2), a pressure tank (7) with a pressure gauge (5) and a pressure switch (6) installed on the five-way fittings (4), form a pressure booster pump. When the pressure in the system drops (e.g., by opening the tap) below the set on pressure, the pressure switch automatically switches on the pump and shuts it off when the set cut-off pressure is reached. In case of water shortage in the well and if we have dry running protection installed, the switching device turns off the pump and protects it from damage. The dry running protection switchgear will then not allow the pump to switch on until sufficient water level in the borehole has been reached.

For trouble-free operation of the system, it is always necessary to observe the correct setting of the air pressure in the expansion tank, which should be 0.2 bar lower than the on (bottom) pressure on the pressure switch. This pressure must be set in the dry state of the tank, i.e., before the actual installation in the system.

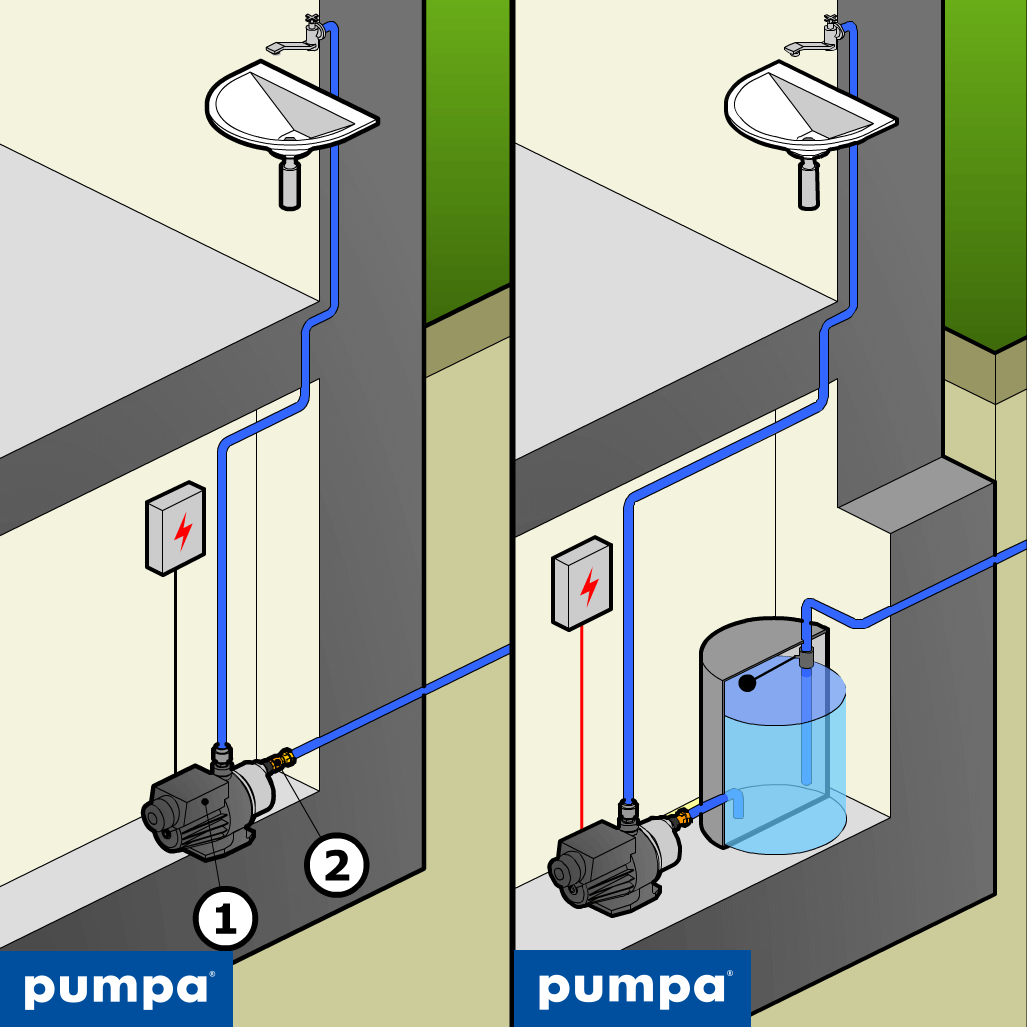

Increasing the pressure of tap water

How the water pressure boosting device works

Principle

In case that an object (e.g., a house) is connected to a water supply system with insufficient pressure, it is necessary to use a device for increasing the water pressure. Direct connection to the water supply network can be used only with the consent of the administrator of the public water supply network. In this case, it is necessary to use a swing check valve on the inlet (2) and the pressure boosting device itself, which can be a pressure booster pump, a compact automatic machine (1), or pressure booster set

In case of disagreement of the administrator of the public water supply network with the direct connection, it is necessary to use a separating non-pressure tank, which is provided with a float valve at the inlet. From this tank, the object is supplied with water using a pressure booster pump, a compact automatic machine, or a pressure boosting. In both cases, it is necessary to protect the pump from dry running.

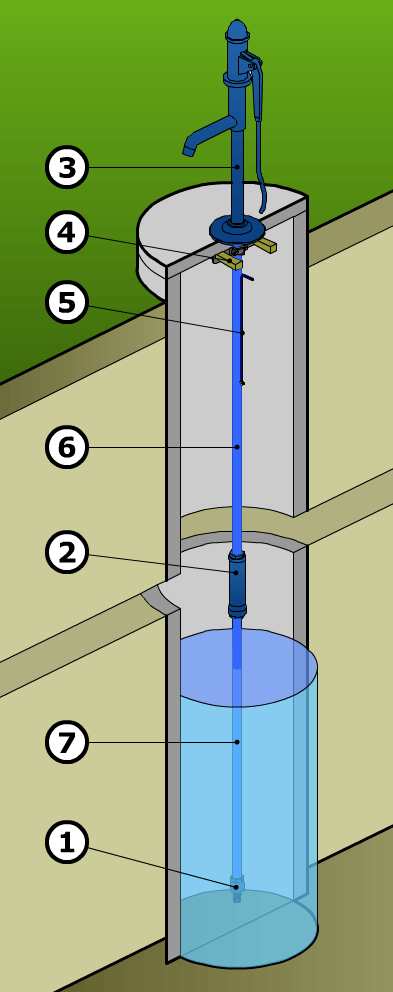

Water supply from the well using a hand pump

How the hand pump works

Principle

Hand pumps are designed to pump water from depths of up to 30 m. Depth of the well determines the type of hand pump and working cylinder. The standard equipment of the set with a manual stand pump (3) consists of a suction basket with a swing check valve (1), a working cylinder (2), drainage (5) and a clip with wedges (4). Furthermore, the working cylinder (2) is connected to the suction basket (1) by a 5/4" pipe (7) and to the hand pump (3) by a 6/4" pipe (6), in which there is also a rod that mediates the transfer between the hand pump lever (3) and the piston of the working cylinder (2).

For pumping water from depths of less than 8 m, we can use hand pumps of the NP or LILA, where the working cylinder is part of the pump.